All my pieces are made entirely by hand using largely modern methods and materials. In their design, however, they are very closely based on originals and it is my goal to make swords that match the handling and performance of the very best originals still in existence.

In the process of ordering a piece, the customer and I discuss the details of the commission. All my pieces are unique, one-off customs that won’t be made a second time. I might of course re-visit the theme. Once we reach an agreement and I can start working, I ask for a non-refundable 20% down-payment. The rest of the price is to be paid after completion, if the customer is happy with the end result.

I do not have a waiting list. I work on a case-by-case basis, only taking on new commission when an older one is completed. I work on no more than two pieces at a time (not accounting for the customization service). If you wish to commission a piece, contact me and I will let you know if I have a free slot and if not, when the next slot will likely open up.

The turn-around time for a sword depends heavily on my free time. I am not doing this full-time and can only work when my full-time job (and life) permits. In general, I would assume a 10-12 month turn-around time, starting the moment I receive the down payment (I will let you know when you can send it, i.e. when I’m ready to start on your piece). The piece may also get done sooner or later, for that I unfortunately cannot give any guarantee. I will always keep you up-to-date about the state of your commission though.

Now, after all this boring but necessary business talk, please follow me as I take you along on the build of a XVIIIa longsword…

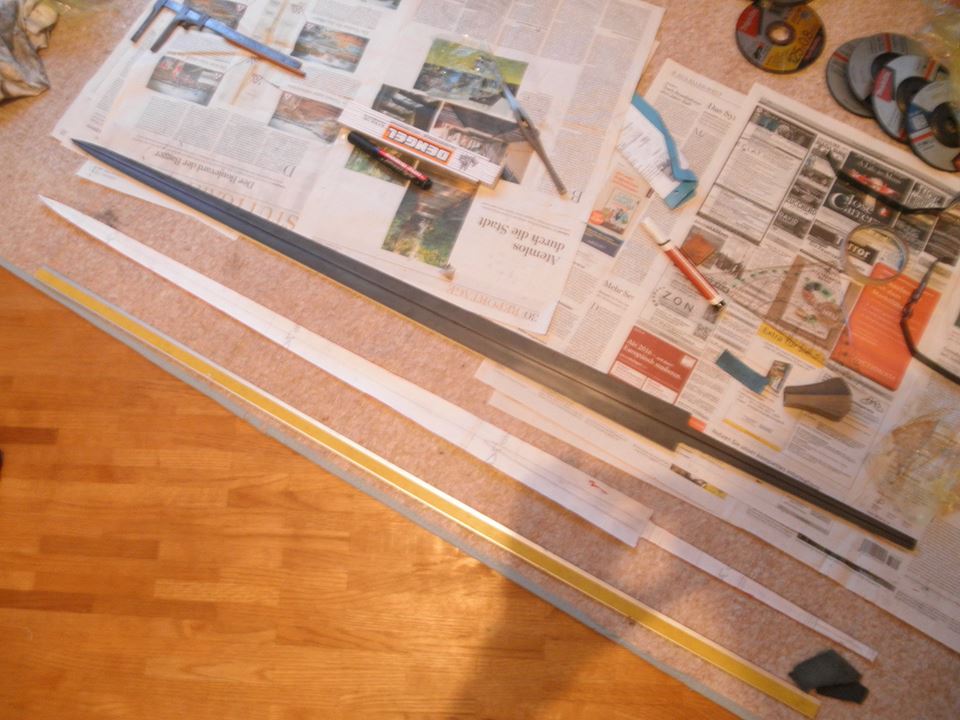

It all begins with a full size drawing. The paper template is then transferred onto a piece of 56Si7 spring steel (thickness varies depending on the sword) and the blade blank cut out.

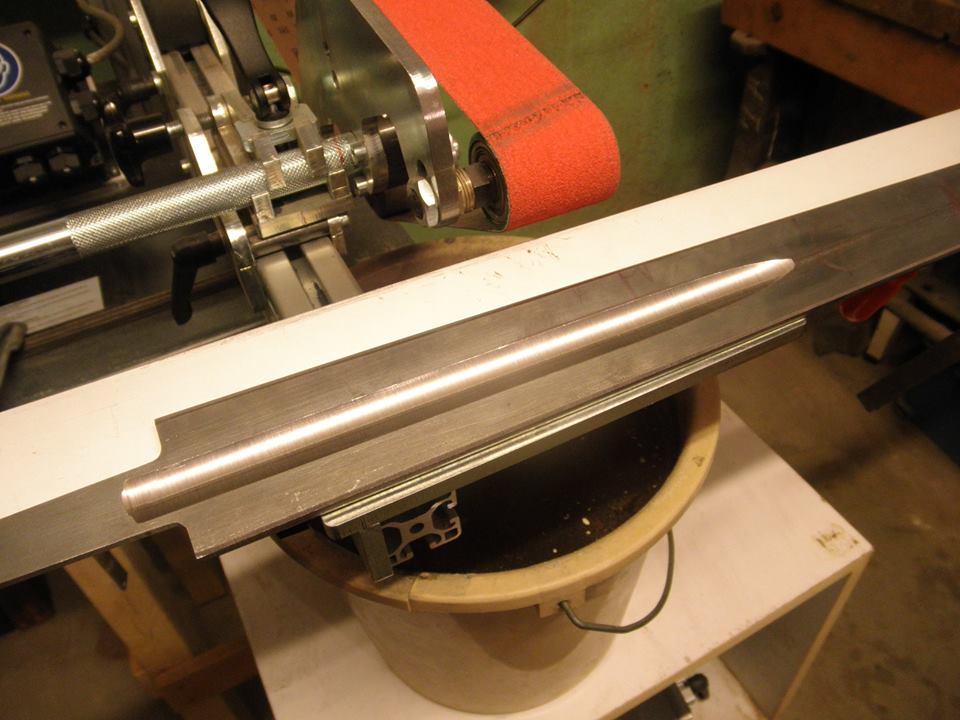

The type XVIIIa calls for a fuller in the lower third. It is ground in with the belt sander.

Then the distal taper as well as the bevels are ground in using an angle grinder.

The blade is then cleaned up on the belt sander. It is now ready for heat treatment.

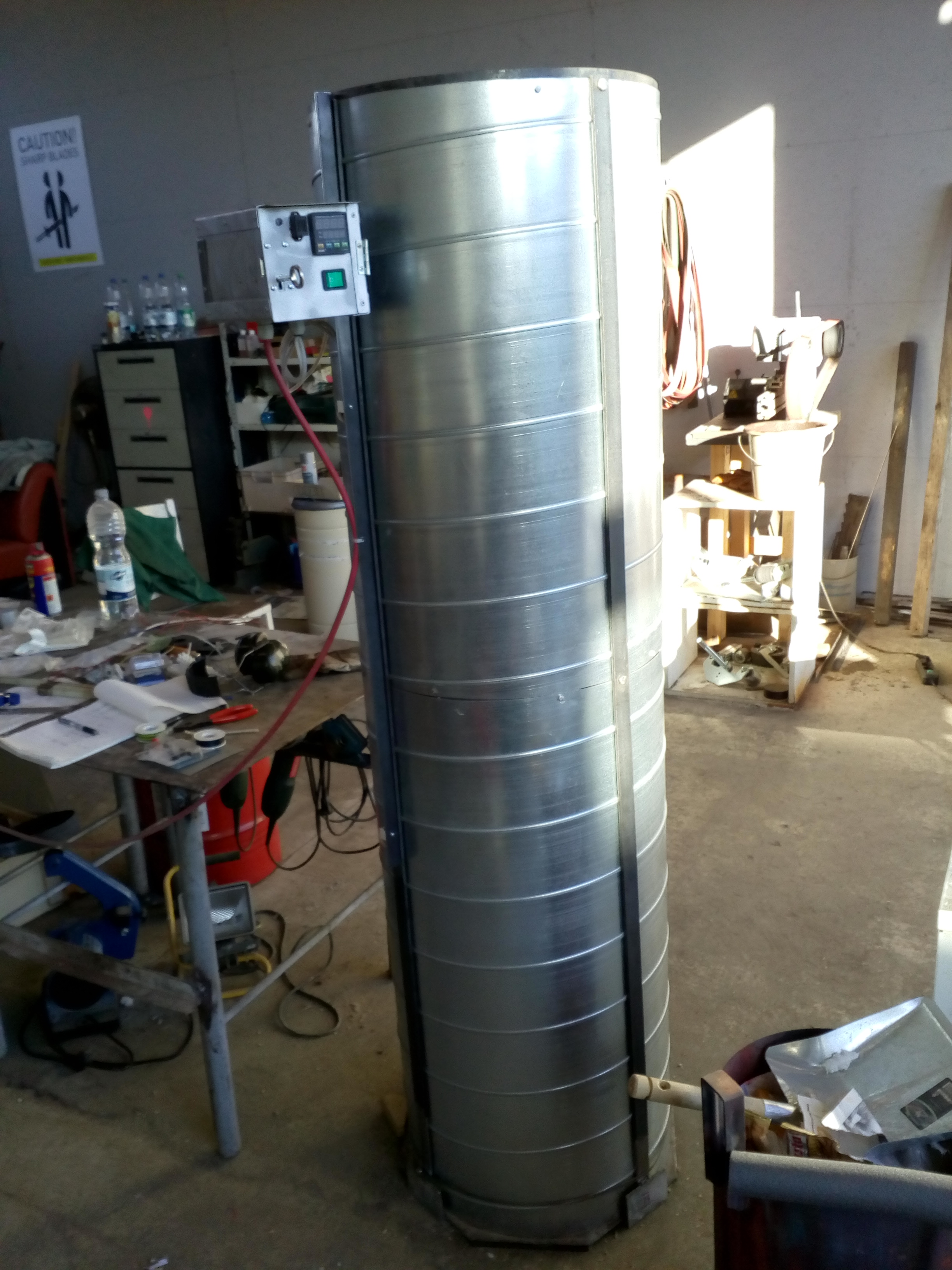

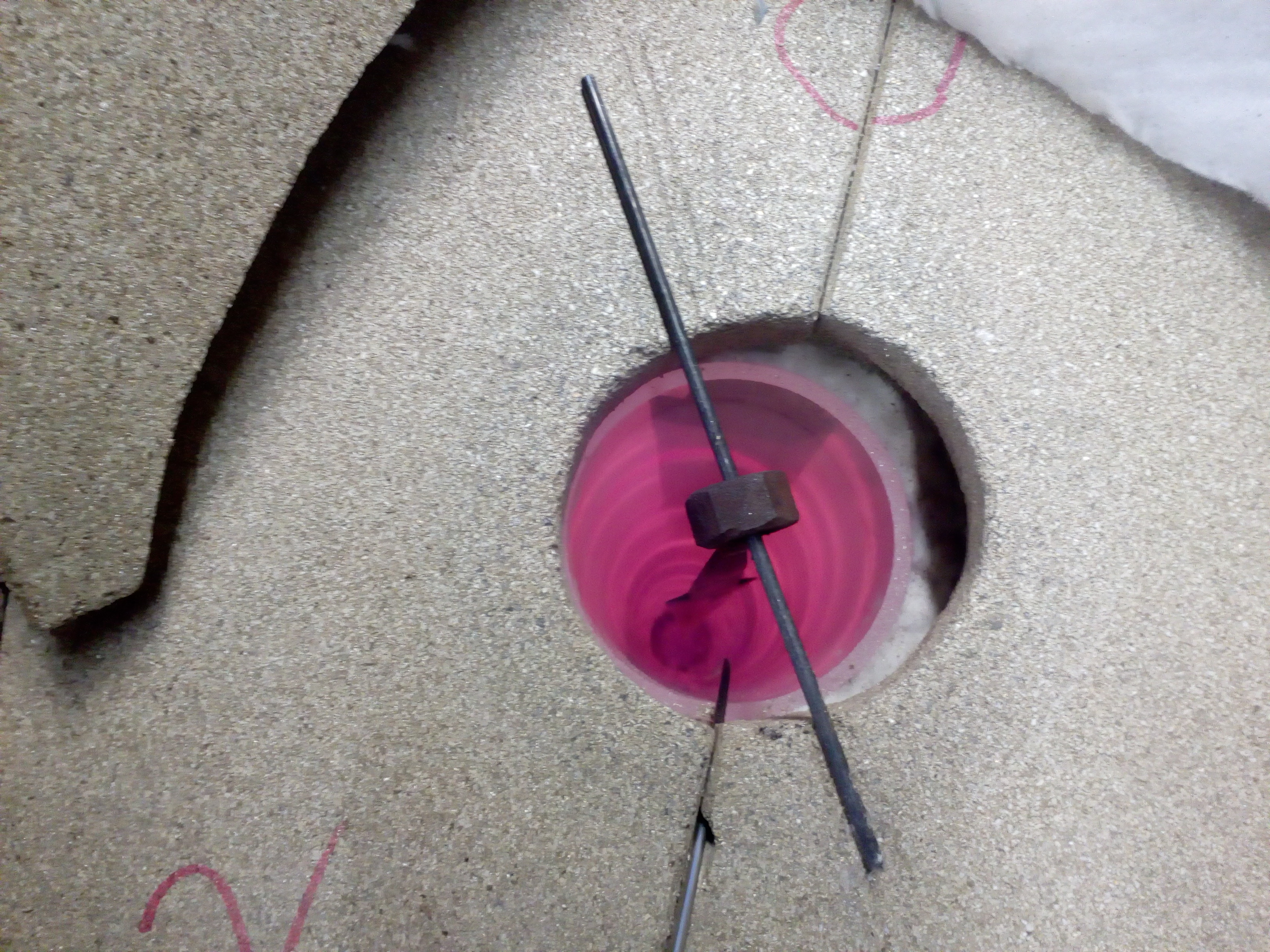

Heat treatment is done in a vertical electrical heat treating oven that allows for very precise temperature control. The blades can be heated in a hanging position, a huge plus to reduce warpage. The blades are quenched in vegetable oil and then tempered. Target hardness is 57-58Rc.

Guard and pommel are usually crafted from mild steel. Both forging and stock removal methods are used.

After the blade has been heat treated and final ground, all components are fit together and everything is polished and the blade sharpened. The guard is then wedged and backpeened in place, the pommel wedged and the tang end hot peened.

A wooden grip is made and glued to the tang. I use UHU Endfest 300 for this, a modern high strength epoxy.

Finally, the wooden core is wrapped in string and then covered with leather.

After applying my maker’s mark as the last step, the sword is now complete.

I do not usually supply my swords with scabbards. To be honest, I don’t particularly enjoy making them, I much prefer working steel instead of wood and leather. Nonetheless, I do make scabbards from time to time (as in this case) and when I do, this is how:

It starts with tracing the blade outline on 2.5mm maple or beech slats.

The slats are shaped, oiled fur is glued on the inside and both pieces joined by wrapping with linen soaked in hide glue. The glue is left to dry with the sword in the scabbard, as it dries, the linen forces the wood to shape around the blade. This makes for a very closely fitting scabbard core.

The fit is such that the sword can be held up-side down without sliding out yet it takes only a firm little tug to draw. It may not be a scabbard for quick-drawing contests but those are not part of the European Martial Arts tradition and I personally value a secure fit over extreme easy of drawing.

The dried core is sanded smooth and the covered in leather. Finally a suspension is added.